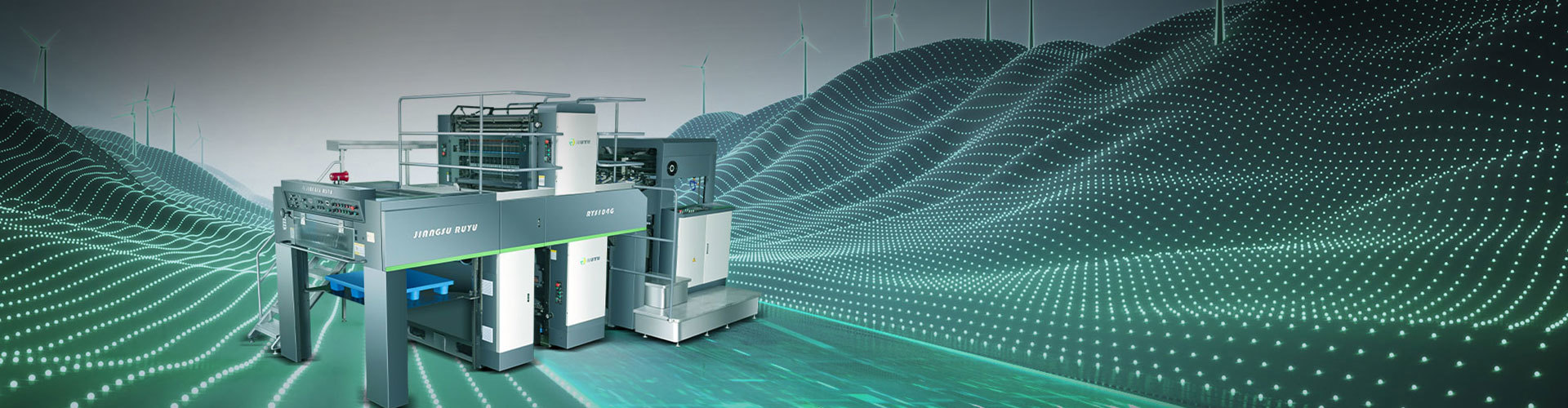

→ This machine adopts the method of "hard pressing and soft", that is, the paper is rolled through between the embossing and the blanket cylinder, which improves the quality of the printed product. → Pneumatically control the ink roller, which can be lifted and dropped for easy operation. → The upper plate cylinder is equipped with axial and radial fine-tuning devices, which can make micro adjustments to the upper plate cylinder without stopping. → The gear material is made of alloy steel, and the teeth are made by high-frequency quenching and fine grinding, with high precision and good wear resistance. Rain type lubrication, has a higher service life. → All rollers adopt high-point closed teeth, strong teeth, accurate overprinting, and ensure the accuracy of paper transfer. → All rollers are supported by bearings. Reduce running resistance and increase speed. → The use of frequency conversion control technology saves electricity consumption.

Learn More →

→ Advanced "reverse first, then forward" split-layer "hard-press-soft" printing method. → Small footprint and large operating space. → The paper transfer path is short and the paper stretches less. → High-speed paper feeder, variable speed feeding, smooth feeding. → Share a mouth, use high-point closed teeth, and the mouth is flat, which is conducive to post-press processing. → The upper and lower printing plates can be used for axial and circumferential electric precision printing without stopping. → Higher printing speed, lower running noise, convenient operation, safe and reliable.

Learn More →

→ With high-speed double-sided offset press as the carrier, a high-precision detection system unit is added, which is mainly suitable for printing and high-precision online intelligent detection of confidential documents, various manuals, test papers, answer sheets, books, maps, etc. → The front and back of the paper can be removed before printing, and the detection accuracy can be improved. → 5 minutes fast modeling, powerful learning ability. → Special algorithm for small text detection, high detection accuracy and accurate detection. → Detailed inspection statistics report, and has the function of screening defective products by page number. → Advanced blowing and flattening technology prevents paper from flicking and ensures high-precision detection.

Learn More →

→ Advanced "reverse first, then forward" staggered "hard-press-soft" printing method. → A large number of imported brand accessories are used at all costs. → High printing quality, using Ruyu registration system, accurate registration. → The optional ink circuit clutch system "2+2" becomes "1+1" or "2+1" in seconds → The third-generation electric cable-stayed version is standard. → Large operating space and higher security. → More reasonable machine structure layout and more comfortable operation interface allow the captain to control easily. → Decades of experience in manufacturing multi-color offset presses for manufacturing and assembly, guaranteeing high reliability and long life

Learn More →