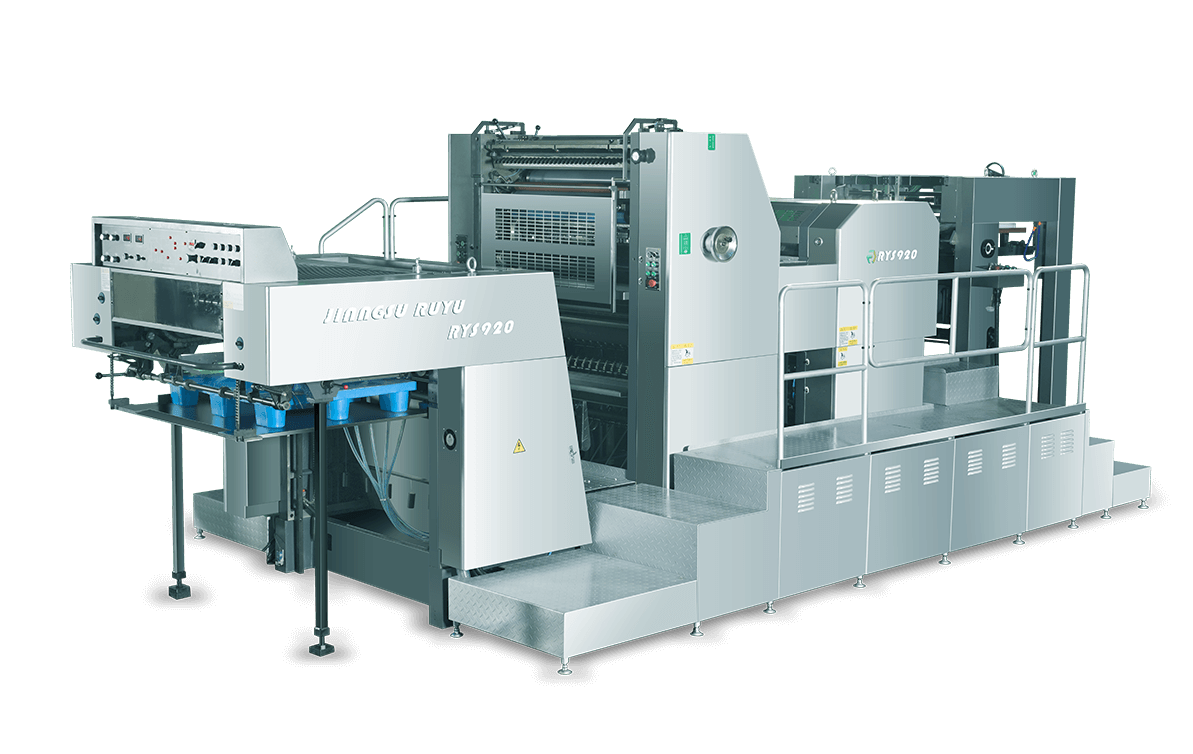

Double-sided monochrome series

Key Word:

Double sided printing machine | printing inspection machine | printing machinery

Category:

Service Hotline:

Double-sided monochrome series

→ This machine adopts the method of "hard pressing and soft", that is, the paper is rolled through between the embossing and the blanket cylinder, which improves the quality of the printed product.

→ Pneumatically control the ink roller, which can be lifted and dropped for easy operation.

→ The upper plate cylinder is equipped with axial and radial fine-tuning devices, which can make micro adjustments to the upper plate cylinder without stopping.

→ The gear material is made of alloy steel, and the teeth are made by high-frequency quenching and fine grinding, with high precision and good wear resistance. Rain type lubrication, has a higher service life.

→ All rollers adopt high-point closed teeth, strong teeth, accurate overprinting, and ensure the accuracy of paper transfer.

→ All rollers are supported by bearings. Reduce running resistance and increase speed.

→ The use of frequency conversion control technology saves electricity consumption.

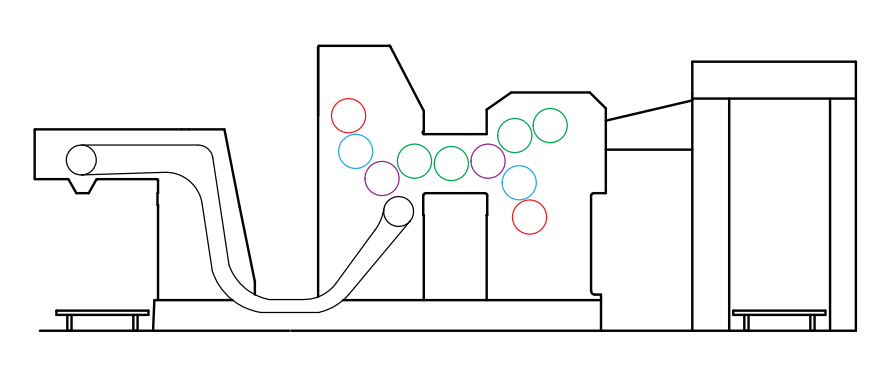

Structure diagram

Technical Parameter

| Model | RYS920/RYS920B Hydrate/Alcohol dampening | RYS1040/RYS1040B Hydrate/Alcohol dampening |

| Maximum paper size mm | 650×920 | 720×1040 |

| Minimum paper size mm | 393×546 | 393×546 |

| Maximum printing area mm | 640×920 | 710×1040 |

| Maximum operating speed r.p.h | 10000 | 10000 |

| Paper thickness mm | 0.04-0.2 | 0.04-0.2 |

| Plate size mm | 950×765×0.28 | 1055×800×0.28 |

| Blanket size mm | 960×900×1.9 | 1065×960×1.9 |

| Backing paper mm | 950×770×1 | 1055×800×1 |

| Paper table height mm | 1000 | 1000 |

| Delivery table height mm | 910 | 910 |

| Machine size mm | 6800×3700×2350 | 6800×3800×2350 |

| Total machine power kw | 30 | 30 |

| Main motor power kw | 15 | 15 |

| Machine weight T | 16.8 | 18 |

| Axial borrowing volume mm | -2 ~+2 | -2 ~+2 |

| Amount of borrowed edition in surrounding directions mm | -0.8 ~+ 0.8 | -0.8 ~+ 0.8 |

Related products

Product message